How To Find Borescope Camera Url

What Is a Borescope?

A Borescope is an instrument used to inspect the within of a structure through a small-scale hole.

Industrial Borescopes

Industrial borescopes permit for remote visual inspections (RVI) in areas where it is difficult or incommunicable for the human eye to encounter into direct. Notwithstanding, the term "borescope" has get a generic term to depict iv types of products/technologies used for internal inspections. While there are fundamental differences between these inspection cameras, the primeval RVI product was called a "borescope" – the name stuck even every bit new technologies were developed.

Borescopes serve a multitude of applications including aviation, aerospace, sanitation, automotive, weaponry, metal casting, law enforcement, electronics, refining, and ability generation. In order to adjust a diversity of industries, borescopes vary in length, diameter, and functionality. To answer the question "What is a Borescope?", let'due south accept an in-depth wait at each blazon of borescope.

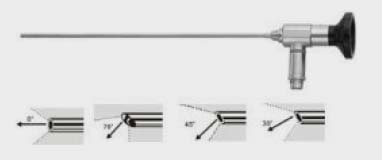

Rigid Borescopes

Remote visual inspection has been effectually for approximately 80 years. In Earth War II, the earliest models of rigid borescopes were used for interior bore examinations in large guns.

Remote visual inspection has been effectually for approximately 80 years. In Earth War II, the earliest models of rigid borescopes were used for interior bore examinations in large guns.

Rigid borescopes, still used for gun barrel or borehole inspections today, are ideal for applications that require only straight-line admission to an inspection target. Rigid borescopes are uncomplicated tubes shaped like long, thin telescopes that utilize a lens organisation to send an epitome to a relay lens from the object to be viewed in real-time. This is achieved with an eyepiece on the proximal (most) cease and an angled mirror pointed toward an opening in the tube on the distal (far) end.

While rigid scopes have excellent paradigm quality, they are limited to only accessing internal parts that can be viewed in a direct, straight line. In addition to gun barrels, they are ofttimes the all-time option for very small bore, direct pipe, or small part inspection, but exercise not piece of work well for viewing within objects with irregular internal cavities.

Semi-Rigid Scopes

A pace up from rigid borescopes, semi-rigid borescopes are bendable and best for confined spaces that do not offer room for joint. Semi-Rigid borescopes are more forgiving and durable than the rigid borescope, which is mainly due to technological progressions and their power to bend. However, they are known for having a poorer image quality than other types of borescopes, which may deter companies requiring loftier-resolution image viewing.

Some of these semi-rigid scopes are also classified as fiberscopes, which are offered in semi-rigid and articulating forms. The image will endure from pixelation; the viewing screen and photos volition brandish tiny black dots acquired by the broken pixels. Once the strands starting time to break down, there is no repairing them and the unabridged unit will have to be replaced.

The best style to ensure the VJ-3 mechanical articulating borescope is the right choice for your company is to try the borescope for gratis at your facility.

Fiberscopes

Fiberscopes arrived on the marketplace almost 35 years ago with the development of fiber optics, which are extremely thin strands of glass. Fiberscopes bundle together anywhere from iii,000 to peradventure 30,000 or more cobweb strands. A fiberscope uses these fibers to transmit an image from the lens closest to the object beingness viewed through the bundle to a relay lens. The image captured by the lens can be viewed directly through an eyepiece, or the eyepiece can exist fastened to a photographic camera that displays the epitome on a monitor.

Fiberscopes arrived on the marketplace almost 35 years ago with the development of fiber optics, which are extremely thin strands of glass. Fiberscopes bundle together anywhere from iii,000 to peradventure 30,000 or more cobweb strands. A fiberscope uses these fibers to transmit an image from the lens closest to the object beingness viewed through the bundle to a relay lens. The image captured by the lens can be viewed directly through an eyepiece, or the eyepiece can exist fastened to a photographic camera that displays the epitome on a monitor.

1 of the main advantages of fiberscopes over rigid borescopes is that fiberscopes are flexible and can exist used for inspections in which directly-line access is not available. While some fiberscopes are also classified as "semi-rigid", fiberscopes are also available with joint. Articulation in a borescope means that the distal 2 inches or so of the scope's insertion tube can be pointed in whatsoever direction, usually by means of command knobs located at the proximal end. In other words, the first few inches of the inspection tool that get inserted into the object are steerable or "controllable" by mechanisms on the unit of measurement that is closest to the inspection technician.

Articulating fiberscopes are the closest option to video borescopes in terms of quality and aptitude. Even so, in that location are some downsides to fiberscopes. Many of the low-price fiberscopes, carried by automobile parts stores, for example, use elastic fibers instead of glass fibers. The epitome quality for these scopes varies among unlike models depending on the number of fibers. For fiberscopes, transparency of the fibers straight relates to image quality. IE: Looking through a plastic drinking glass would be more difficult than looking through a glass i.

Another disadvantage of fiberscopes is that if whatsoever of the fiber strands break from rough joint or simple overuse, the image will suffer from pixelation; the viewing screen and photos will display tiny black dots caused by the broken pixels. Once the strands start to suspension downwardly, in that location is no repairing them and the entire unit will have to be replaced.

Video Borescopes or Videoscopes

Videoscopes, the well-nigh contempo development in inspection camera engineering science, are similar to fiberscopes in that that in that location are both articulating videoscopes and non-articulating videoscopes. The main mechanical difference between videoscopes and fiberscopes is that a videoscope has a micro video photographic camera and light located at the far cease of the insertion tube. The camera straight captures the inspection image and electronically carries the video signal downwards the insertion tube to a video processor and brandish. This process results in a much higher resolution image quality, without the threat of pixelation that occurs in fiberscopes.

Videoscopes, the well-nigh contempo development in inspection camera engineering science, are similar to fiberscopes in that that in that location are both articulating videoscopes and non-articulating videoscopes. The main mechanical difference between videoscopes and fiberscopes is that a videoscope has a micro video photographic camera and light located at the far cease of the insertion tube. The camera straight captures the inspection image and electronically carries the video signal downwards the insertion tube to a video processor and brandish. This process results in a much higher resolution image quality, without the threat of pixelation that occurs in fiberscopes.

High-quality prototype and video capture brand videoscopes a valuable tool in numerous industrial and commercial applications, specially for repair and routine maintenance inspections. They are ordinarily used in the remote visual inspection of engines, turbines, boiler systems, power institute equipment, industrial equipment, structures, and constabulary enforcement situations.

Like the unlike types of borescopes, videoscopes are not one-size-fits-all. The most mutual characteristics that decide which model is all-time for a detail application include articulation, epitome quality, portability, weight, required power source, visual display clarity, image or video capture capabilities, insertion tube length, and illumination. Typical RVI applications require a lightweight, portable borescope that does not require a "plug-in" ability source. Other features commonly sought later on by maintenance professionals are one-hand functioning, crystal clear images and videos, and an power to "steer" the borescope camera. Any borescope that can exist "steered" is known equally an articulating borescope.

Costs for loftier-end video borescopes tin range from about $8,000 to $50,000 depending upon manufacturer, configuration options, and specifications. While the cost might seem high to some, it is oft nowhere near the cost associated with equipment downtime that tin can occur when regular preventative maintenance inspections are non being performed. Whether you are using a depression-end rigid borescope or a video borescope with high-end features, the question should not exist "What is the toll of this tool?", just "What is the cost of non owning this tool?"

VJ-3 Articulating Video Borescopes

VJ-3 industrial videoscopes offer tremendous value for an industrial-class portable borescope. Nosotros offer all of the features, such as four-mode joystick-controlled articulation and a medical grade camera, desired in an industrial inspection camera at an extremely competitive price point.

VJ-3 industrial videoscopes offer tremendous value for an industrial-class portable borescope. Nosotros offer all of the features, such as four-mode joystick-controlled articulation and a medical grade camera, desired in an industrial inspection camera at an extremely competitive price point.

Remote visual inspection with a quality video borescope tin save many hours that would otherwise exist required to disassemble and inspect internal components of critical systems. The VJ-3 is well-suited for a wide range of commercial and industrial inspection scenarios.

Observe out more almost the numerous features offered on a VJ-3 articulating videoscope past visiting our products page. If yous have a borescope repair service that must be completed, ViewTech tin aid.

Request To Rent A Video Borescope

Complete the form below and one of our representatives will piece of work with you to secure a rental borescope.

Telephone call united states of america at 231-943-1171

– Or –

Make full out the class below and ane of our representatives volition contact you.

Source: https://www.viewtech.com/what-is-a-borescope/

Posted by: cooktheartumety.blogspot.com

0 Response to "How To Find Borescope Camera Url"

Post a Comment